Glass. A subject often relegated to the depths of inconspicuousness. It’s the transparent thing that offers a clear layer of protection from the elements in an automobile. When did you hear anyone passionately discussing the windshield in a car club meet? And because of its transparency, glass is often thought to be brittle. Not exactly a comforting thought while you gaze at the stars in a vehicle doing highway speeds.

Of course, it doesn’t have to be that way. In the very unlikely event of an accident, people need to know that glass is an important part of an automobile’s protective shell. Automotive glazing is a far tougher material than most vehicle owners think. It has to be. Glass should be engineered to safeguard the lives of a car’s occupants.

Glass, in its purest form, is a transparent, fragile substance that is commonly used in bottles. While the method of its manufacture allows it to be flat, it is far from suitable for automotive application. Ordinary glass breaks in large, heavy fragments, which can seriously injure anyone being struck by them in an accident. This is why for automotive purposes, the use of safety glass is imperative.

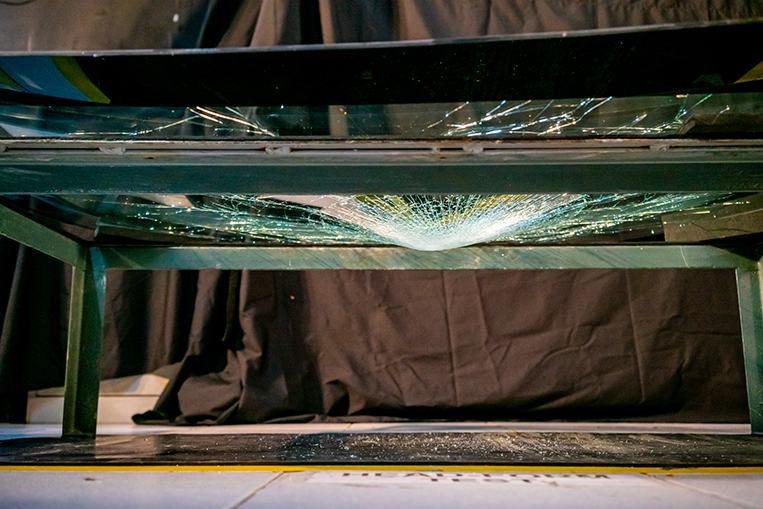

Laminated glass is what windshields are normally made of. A thin layer of flexible plastic film is sandwiched in between two slim panes of glass. Instead of the fragments scattering upon impact, these are held together and contained by the layers of plastic film that stretches as it absorbs the energy of the collision.

Tempered glass, on the other hand, is used for side and rear windows. It behaves differently from laminated glass upon impact. Because tempered glass is rapidly cooled after the heating process, this type breaks into tiny fragments upon impact. However, these pieces are small enough to cause minimal or no injuries.

As with anything meant to be installed in automobiles, safety glass undergoes a comprehensive battery of tests to check its suitability for use in cars. And the word “suitability” doesn’t simply mean a component designed to work with the car. Accurate and Precise Inspection and Testing Laboratory Inc. (APITLI) knows all too well that human lives depend on glass being as safe as possible.

APITLI is ISO 17025:2005-accredited, which means that this is an organization that operates competently and generates valid results. The company also complies with the standards set forth by the Philippine Accreditation Bureau, which is responsible for certifying firms that offer conformity-assessment services. As PAB is a signatory to the International Laboratory Accreditation Cooperation, APITLI’s testing procedures and results satisfy international standards.

To test for vision, streams of light and a series of images are beamed through the glass. In addition, the amount of visible light transmitted through the glass is also evaluated. These steps are crucial in order to check if the glass does not impair the driver’s vision in any way, and if the sight picture remains consistent throughout the pane. A passing grade means passengers can clearly see objects throughout the glass, whichever part of it they look through.

Another important test is for safety. Obviously, the whole point of having glass acceptable in cars is to make it, at the very least, capable of preventing further injury to occupants in an accident. To that end, laminated glass is subjected to a slew of high-velocity impacts from projectiles of varying sizes. These tests check if the integrity of the glass remains intact by preventing the penetration of these projectiles, and ensure that any fragments resulting from the impact are contained by the lamination. Tempered glass, meanwhile, is designed to shatter into very small pieces. Test samples are destroyed and the fragments are assessed if their sizes conform to what is acceptable for safety.

Lastly, safety glass needs to withstand prolonged exposure to heat and humidity. After all, any ounce of safety built into automotive glazing will be for naught if the latter’s integrity crumbles under the heat of the sun. Sealed chambers simulate high temperatures and extremely damp ambient air. The glass specimens are placed in these enclosures and left to literally boil for several weeks just to see if they can withstand the extreme conditions that our country’s tropical climate can throw at them.

Anyone can feel confident knowing that glass is a safeguard against the elements. As APITLI’s expertise in the evaluation of automotive glazing has shown, there is more to the material than its clarity. It is both a work of art and a breakthrough of science and technology.

This branded article was produced in partnership with Accurate and Precise Inspection and Testing Laboratory Inc.

Comments