Video games—a world where anyone could be anything, even if it’s just a few thousand pixels on a television screen. You could be a chubby Italian plumber saving a princess from an evil turtle, or you could be Lewis Hamilton screaming through Silverstone’s Hangar Straight. It is in video games that the concept of virtual reality—a three-dimensional computer-generated environment that people can interact with—was born. Virtual reality used to be the realm of video games and full-motion flight simulators, but now your next car is being designed by dudes wearing lab coats and 3D glasses.

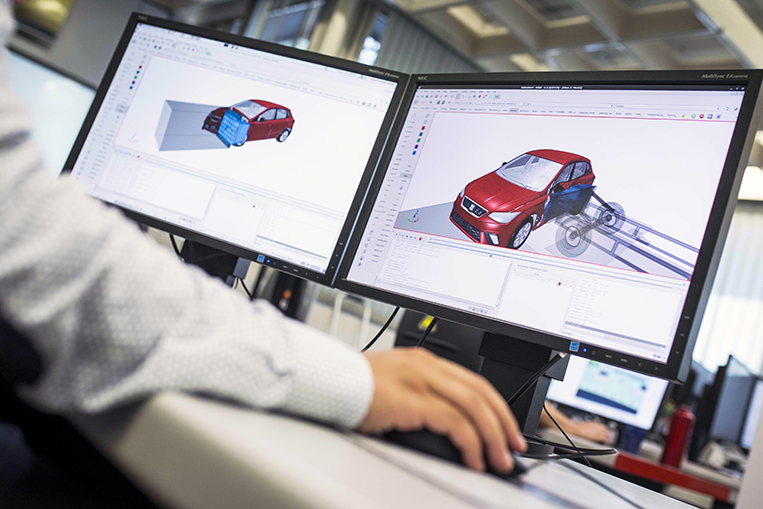

The creation of a new car starts with the design process. These days, this usually involves a lot of drawings using CAD (computer-aided design) software. But automakers recognize the limitations of the virtual pen-and-paper and are now using 3D technology to dive into what they’ve designed. By donning a pair of 3D glasses, designers can actually see what future customers would experience with the new vehicle. It is at this stage where not only the creative aspect of the design is evaluated, but also its functional and practical aspects. After all, you wouldn’t want that climate control switch awkwardly placed in the cabin and then have Doug DeMuro point it out in his next video.

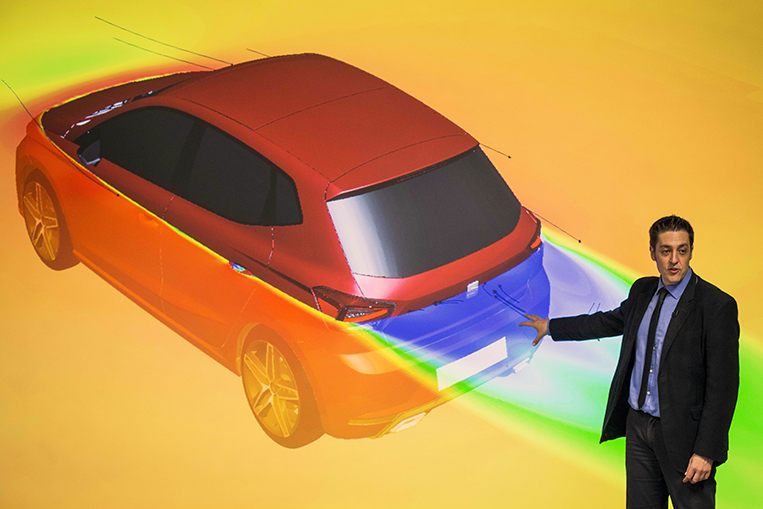

Part of the process of creating a new car is ensuring that every component functions and performs as designed. Simulation used to be a very primitive process that took so long only a very limited number of elements could actually be tested in the amount of time allotted for research and development. Today, computers can perform very complex mathematical calculations so quickly that a crash test can be simulated before an actual car is flung toward a concrete wall at 60km/h. As much as three million elements are analyzed by computer-based testing, which used to be limited to only 5,000 elements 30 years ago. In the case of the new Seat Ibiza subcompact hatchback, 95,000 simulations were performed during the development stage, twice as much as with the previous generation.

The use of virtual reality lets car manufacturers minimize the time and resources needed to produce a vehicle. It allows them to refine and tweak the design on a greater scale

Prototyping is a crucial part of the engineering that goes into a new car. I’m an electronics engineering graduate, and even though I had computer-based tools that did all of the difficult arithmetic, nothing really beats a working prototype to check if I got my sums right. But prototyping consumes time and resources, and in the interest of lowering development costs, carmakers strive to create as few prototypes as possible. With the above-mentioned role of virtual reality in the design phase and early stages of development, the number of prototypes needed is reduced by half. In addition, the time it takes to make one prototype is cut by 30%.

The use of virtual reality lets car manufacturers minimize the time and resources needed to produce a vehicle. The decision-making process is made much more efficient, and as a result, it allows them to refine and tweak the design on a greater scale. Before the Seat Ateca crossover was put into production, over 800 improvements had been made during the design and development phase. Also reaping the benefits brought about by virtual reality is the factory where the cars are built. Technicians at Seat’s Prototype Development Center use 3D glasses and tactile feedback controls to immerse themselves into a virtual assembly line in order to increase efficiency and improve workstation ergonomics.

Finally, virtual reality may potentially play a role in vastly improving the dealership experience. From browsing through paper catalogs, spec sheets and build-and-price websites, customers may now put on a pair of 3D glasses and configure the vehicle’s trim level and optional extras from there. Another likely benefit of this is the virtual test drive experience. Not all customers who purchase cars can drive, and not all dealerships have available test vehicles in the customer’s preferred trim, so the virtual test drive may be the next best way to let the customer experience the car before deciding whether to buy it or not.

Comments